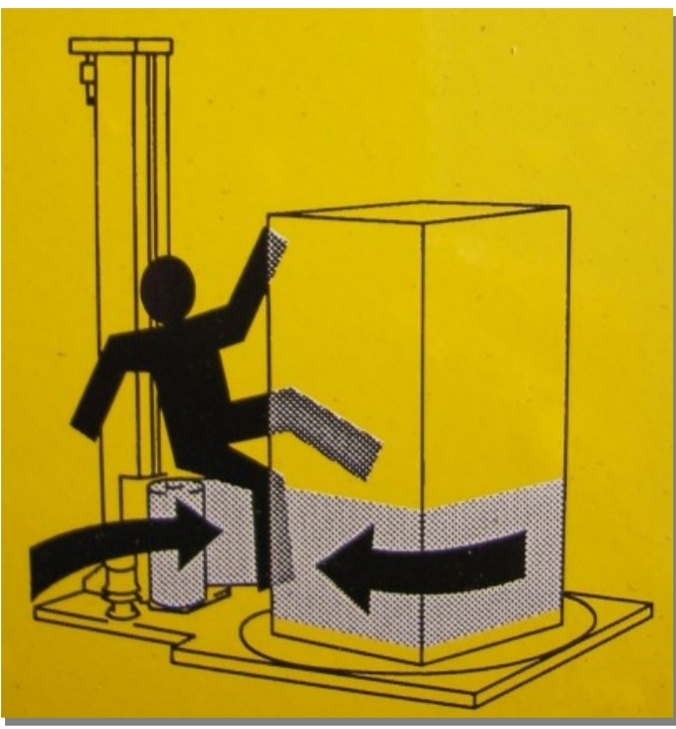

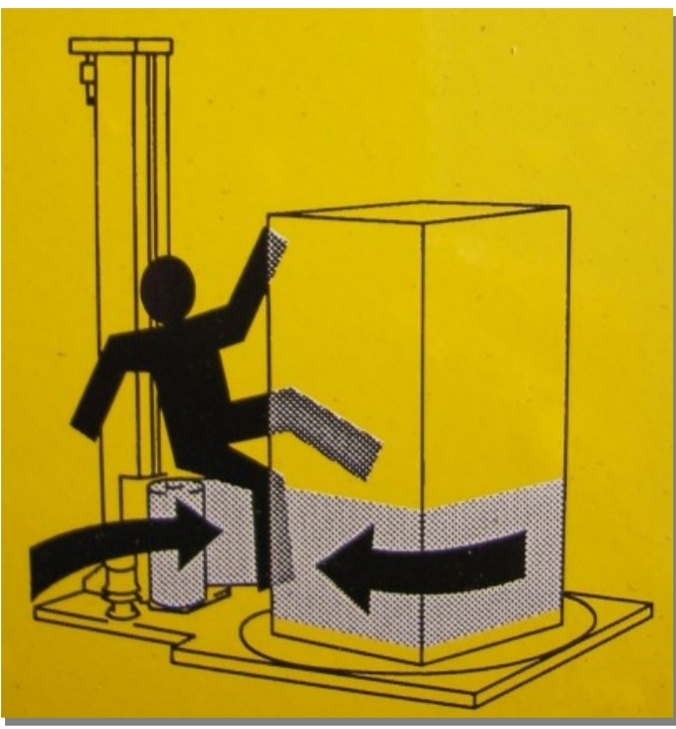

Pallet wrapping machine repair for continuous packaging performance

Exactly How to Make best use of Performance With a Pallet wrapping Maker: Typical Repair Tips

Making the most of performance with a pallet wrapping equipment requires a critical method to repair and maintenance. Normal checks are essential to assure all components work smoothly. Common issues such as inconsistent film tension and jamming can disrupt procedures. Resolving these issues immediately can improve efficiency. Nevertheless, comprehending the nuances of changing tension and preserving cleanliness is equally crucial. What details steps can be taken to assure peak performance?

Routine Upkeep Checks

Regular maintenance checks are necessary for making certain the optimal performance of a pallet wrapping device. These checks not just enhance the longevity of the tools but likewise boost functional effectiveness. Regular examinations must include checking out the machine's electric elements, making sure that all links are cost-free and secure from corrosion. The film dispensing system must be looked for correct placement and stress to stay clear of operational disruptions. Additionally, lubing moving components minimizes friction and wear, maintaining smooth performance. Operators ought to also evaluate the control panel for any type of irregularities in analyses or performance. Routine maintenance promotes a proactive approach to tools treatment, eventually leading to reduced downtime and boosted efficiency in the wrapping process. Sticking to an arranged upkeep strategy is essential for optimal performance.

Repairing Common Issues

Replacing Damaged Parts

Changing worn-out parts is essential for keeping the ideal efficiency of a pallet wrapping machine. Routine evaluations aid recognize parts that show indicators of wear, such as the film carriage, rollers, or drive belts. These components can deteriorate in time, bring about inadequacies in wrapping operations. It is vital to select top notch components that match the machine's specs to assure compatibility and optimal efficiency when substitute is essential. Service technicians should follow the maker's standards throughout the replacement process, as improper setup can cause further problems. Furthermore, maintaining a supply of frequently required parts can decrease downtime, enabling for quicker fixings and maintaining efficiency degrees. Aggressive maintenance and prompt substitutes are crucial to extending the equipment's lifespan.

Adjusting Tension and film Settings

Maintaining suitable performance of a pallet wrapping maker extends beyond replacing worn-out components; it additionally includes adjust the stress and film settings. pallet wrapping machine repair. Correct stress is important for attaining optimum load stability during transport. If the tension is as well tight, it may harm the load, while inadequate tension can result in loose wrapping and possible changing. Operators ought to consistently inspect and readjust the tension settings according to the specific requirements of the load being covered

Additionally, selecting the right film kind and density is necessary for making sure efficient wrapping. Thicker films use improved strength yet may require greater tension setups. On the other hand, thinner films might be a lot more affordable yet can jeopardize load safety and security otherwise effectively tensioned. Routine changes will certainly make the most of effectiveness and lessen material waste.

Keeping the Equipment Tidy and Moisturized

Although usually ignored, maintaining the pallet wrapping equipment clean and lubricated is essential for making certain peak efficiency and durability. Normal cleaning assists protect against the accumulation of dirt, debris, and residue that can prevent mechanical functions. It is advisable to clean down surface areas and eliminate any collected products after each use. In addition, proper lubrication of moving parts minimizes friction, minimizes wear, and prolongs the life-span of the machine. Operators ought to consult the manufacturer's guidelines for suggested lubricating substances and maintenance schedules. Performing routine assessments to recognize any kind of indicators of rust or rust can additionally avoid even more considerable concerns down the line. Sticking to these methods will certainly not only boost performance yet also advertise secure procedure of the pallet wrapping device.

Regularly Asked Questions

Exactly how Commonly Should I Change the Pallet wrapping film?

The regularity of changing pallet wrapping film relies on usage and wear. pallet wrapping machine repair. Typically, it needs to be replaced when indicators of damage, tears, or excessive extending occur, ensuring optimal performance and defense of the covered products

Can I Utilize Different Kinds Of Movies With My Machine?

Various kinds of films can normally be utilized with pallet wrapping devices, but compatibility depends upon the equipment's specifications. Customers need to consult the manufacturer's guidelines to assure peak performance and prevent possible damage to the equipment.

What Safety and security Preventative Measures Should I Take While Running the Machine?

When running a pallet wrapping machine, one need to put on appropriate personal safety tools, assurance correct read more training, maintain a clear work space, and consistently inspect the machine for any type of potential threats to guarantee safe procedure.

Exactly how Do I Train New Personnel to Make Use Of the Pallet wrapping Machine?

To train new workers on the pallet wrapping equipment, one ought to offer comprehensive presentations, detailed guidebooks, and hands-on session. Routine assessments and comments will boost their skills and guarantee safe, efficient operation.

What Are the Indications That My Machine Demands Specialist Servicing?

Indicators showing a requirement for specialist maintenance consist of unusual sounds, irregular wrapping, frequent error messages, and visible endure elements. Prompt focus to these issues can avoid more damages and guarantee height equipment efficiency.

Regular maintenance checks are important for making certain the optimal performance of a pallet wrapping equipment. Changing worn-out components is essential for keeping the ideal performance of a pallet wrapping device. Preserving perfect efficiency of a pallet wrapping equipment expands beyond replacing worn-out parts; it likewise includes make improvements the stress and film setups. Often overlooked, maintaining the pallet wrapping equipment clean and lubricated is important for making certain peak performance and longevity. Various types of films can typically be used with pallet wrapping devices, but compatibility depends on the device's specs.